What is Beer Filtration

Beer filtration is an important production process in beer brewing, it matters most for beer appearance, taste, bio-stability and non-bio-stability. Beer filtration is to keep appearance from changing at least within guarantee period.

Pasteurized beer after fermentation, a few yeasts and proteins among other coagula suspend in beer, lead it to turbid. So it need to be removed by filtration process.

Beer filtration is a physical process by using filtering media, separating suspended micro-particles from beer, make it crystal clear.

Main Factors to Influence Beer Filtration

| Polysaccharide | Agglomerates formed from polysaccharide |

| Quantity and mol.wt of polysaccharide | |

| Dissolution of malting process | |

| Material type and gum content | |

| Protein | Decomposition and cohesion effect of protein |

| Quantity and polarity of cold sludge | |

| Quantity and mol.wt of protein | |

| Association of hydrophobic proteins | |

| Yeast & Bacteria | Coagulation performance of yeast |

| Isophagy & secretion of yeast | |

| Pollution & secretion of bacteria | |

| Deposition and separation speed of yeast | |

| Brewing Process | Feeding and saccharification temp. |

| Period under high temp. | |

| Various of shearing force in process | |

| Beer storage temp. and period | |

| Solid-liquid separation performance of processes |

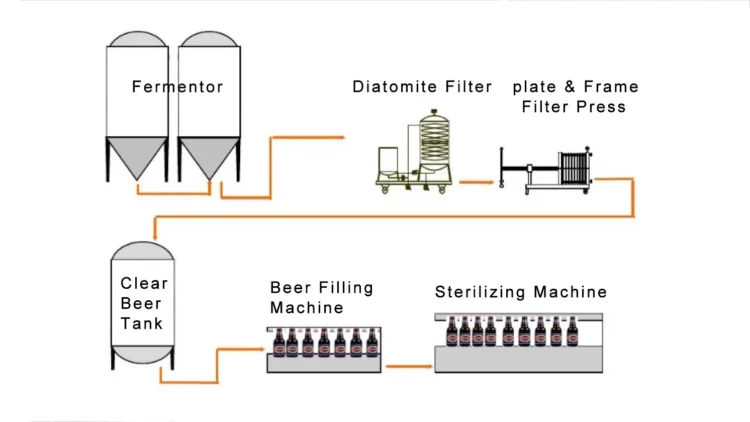

Filtration Process & Operation

Filtering Types

- Pulp filter (cotton cake filter)

- Diatomite filter (coarse filter)

- Paperboard filter (fine filtration)

- Double flow filter

- Cross flow filter(it is used to replace diatomite filter)

- Sterile filter(it is mainly used for the filtration of draught beer)

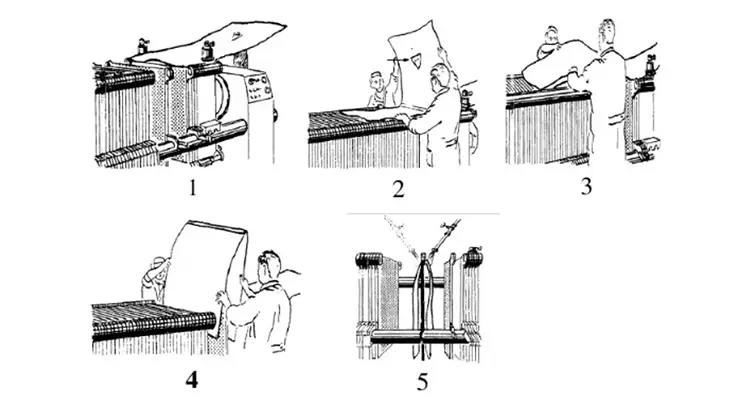

The Operation Guide of Plate & Frame Filter Press

The usage of filtering board

- Preparation before filtration

- The influent & effluent face of filtering board should be noted in installation, the coarse one is influent face, and before installation, filtering board have to be fully soaked. New filtering board we suggest do a sterilization, at least 15 minutes’ rinsing on its first use.

- Check sealing ring, and any misplacement between filtering board before filtration.

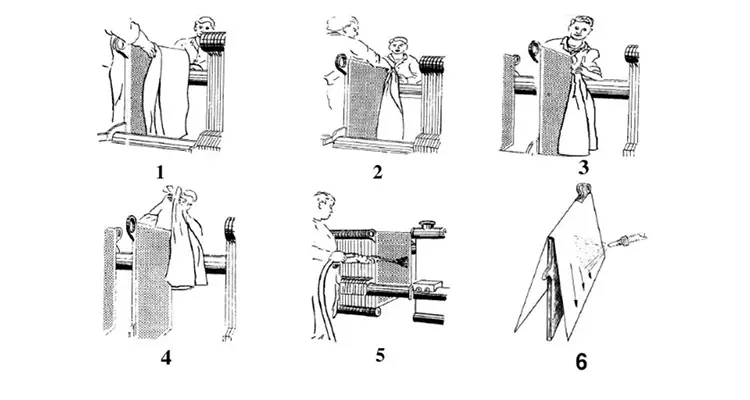

- Pre-painting & Sec-Painting

- Pre-painting is to form a basic filtering layer on paper board, which is to prevent blockage in paper board space by yeast and other stickum, meanwhile extend its service life, and it is also better for flushing after filtration.

- The proportion and quantity of diatomite have to be adjusted and added according to: 1. Performance of diatomite filter press, 2. Diatomite quality, 3. Liquid condition, with reasonable filtering speed to reach beat filtering effectiveness.

- After filtration, slow and soft water used to flush yeast, protein and other matters on filtering paper, the water temperature need to heat at 85℃, make any place in diatomite filter keep this temp. at least 30 minutes. Meanwhile observing whether any fibers drop. Each filtering board normally can be used for 15-20 times.

Operation Mode of Diatomite Filter Press

Operation of Diatomite Filter Press

Basic Procedure:

Pre-coating -> Filtration -> Casting -> Cleaning-> Sterilization

Remarks:

- Why we need to pre-coat? It is to form progressive filtering layer and convenient for diatomite casting after filtration

- How do we do pre-coat?

Pre-coating liquid: tap-water, pure water, etc.

The first time pre-coating is critical, though this layer is not for filtration, but it functions as support layer. Coarse diatomite used for this layer is about 0.7-0.8kg/sq.m, account for approx. 70% of the whole pre-coating content.

- Air-out before pre-coating is premise for good pre-coating.

- Quality demand for pre-coating: consistent thickness, well-distributed coarse and fine diatomite, △p=0.2-0.3bar after pre-coating.

Installation of filtering board

Cleaning of Filtering Board

Q&A about Suspended Matters

We often find white flake, filiform or particle substances appearing in beer during its production and storage. Via components analysis these substances mainly are polymer protein, polyphenol, yeast cell and other solid matters which is separated out mainly due to reach a stable new balance after beer colloids broken. Here below we suggest some advice to decrease suspended substances in beer:

- Material Requirement: malt protein<11%, well-dissolved. Fresh sugar-excluded rice.

- Saccharification: extend protein rest time during saccharification process, adjust production process meanwhile taking account of soar foam performance.

- Boiling: forced circulation pump should be stopped in the later stages of wort boiling, prevent protein from being scattered by strong rolling so as to influence later fermentation.

- Fermentation: increase fermentation depth, enhance yeast cell to take advantage of protein, sugar, etc.

- Culture management: assure bioactivity of yeast cell. The nutrient substance which yeast cell needs should come from wort, it is to adjust wort formation by improving saccharification process and raw material ratio, it is not suitable to use additive so not as lead to performance degradation of yeast.

- Clear beer: strength clear beer filtration, remove protein and yeast possibly, the turbidity of clear beer should be kept below 0.35EBC.